For those of you who still fly with gas or nitro engines, a reliable engine run is paramount, this mainly relies on a good engine and fuel tank setup. To achieve this, at the heart of your setup should be a good quality fuel tank, and the Turnigy range of strong, and flexible transparent fuel tanks does just this. These fuel tanks are supplied with a one-piece machined metal cap which includes a fuel feed nipple, a flexible fuel feed pipe with clunk weight, and 2 factory-installed machined metal 90° hose attachment nipples. The machined metal cap has a gas/nitro compatible sealing washer which provides a perfect leak-free seal, and the factory-installed nipples also have sealing washers inside and out for the perfect seal. One of these nipples is usually used for filling, and the other is used for pressure, or for venting. The fuel feed inside the tank is supplied by a flexible gas/nitro-compatible pipe with a heavy clunk weight. This will ensure the feed pipe stays in the fuel for a reliable fuel feed at all times, this is of course, as long as there is fuel in the tank.

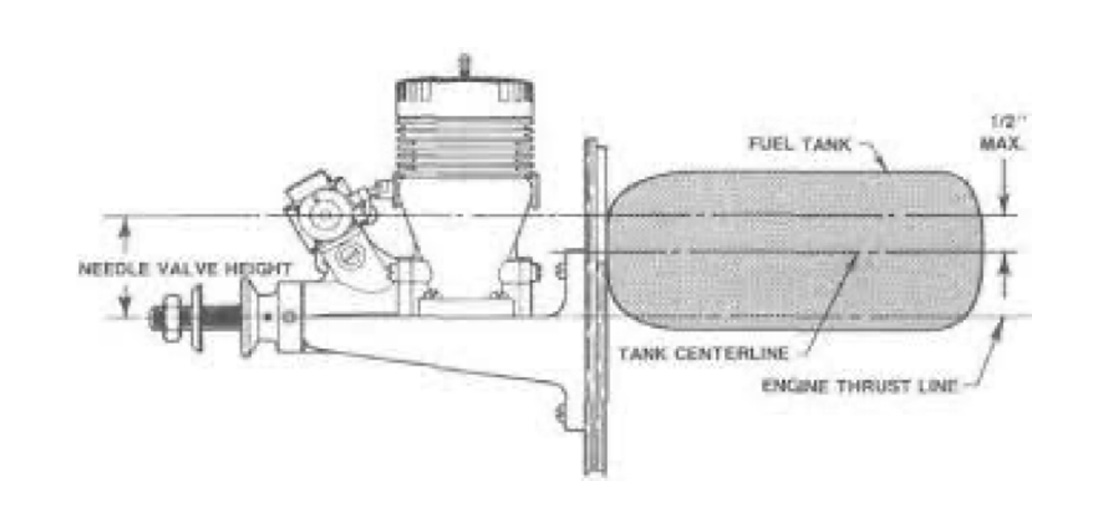

With a gas engine, the positioning of the tank is not so important, this is because gas engines have a carburetor that includes a fuel pump for a constant and reliable fuel feed. Nitro engines do not generally have a pumped carb, so it is very important that the tank is positioned in the model correctly to obtain a constant, and reliable fuel feed in all attitudes. As per the drawing below, the fuel tank should be as close to the engine as possible, it should also have the center line of the tank as close as possible to the center line of the needle-valve assembly on the carb. If you then use exhaust pressure to the tank, and block of the fuel filler pipe with a stopper, this will give a sealed system that will provide a reliable fuel feed to the engine regardless of the attitude of the model when it is flying.

To obtain a reliable nitro engine run in a model airplane, will also require the needle valve to be set correctly. With the model level, tune the engine using the needle valve so that it just breaks into a 2-stroke from 4-stroking. Then raise the nose gently until the model is vertical, it should continue to run evenly, if the engine starts to try to cut out, it is too lean, so open the needle valve a little and try again.

Vibration is also a big cause of erratic engine running, vibration can cause the fuel in the tank to froth, and this frothing creates loads of air bubbles which will cause bad running. To cure this, firstly you need to ensure the propeller, and spinner are correctly balanced, and secondly, the fuel tank needs to be installed in the model encased in a vibration-absorbing foam. Do not try to jam too large a fuel tank into the tank bay so that is touching the sides. Select a size tank that leaves a bit of room to enable you to pack a good vibration-absorbing foam around the tank.

Follow these steps and use a good tank such as these high-quality Turnigy series and you will obtain a reliable engine run, every flight.

Ensure your nitro tank setup is as close to this illustration as you can get to enable a good, reliable engine run throughout the whole flight.

The Turnigy Transparent Gas/Nitro Tanks are available in the following sizes: 260, 360, 500, and 1000ml.

Get the Turnigy TransparentGas and Nitro Fuel Tanks

---

Hear it First: Join our Mailing List

Sign up to receive new product updates, exclusive discounts, news, and more!