In the early 1950s, commercially available "Single Channel" outfits for controlling model aircraft started to become available. These simple systems controlled literally one function on the model, and this would have been the rudder, and it was all done with the press of a single button on the transmitter. All the models being used then were of the "Free Flight" type, they were super stable, had plenty of dihedral, and were usually powered by a small diesel engine.

The Mercury Matador is a typical single-channel model of the 1950s.

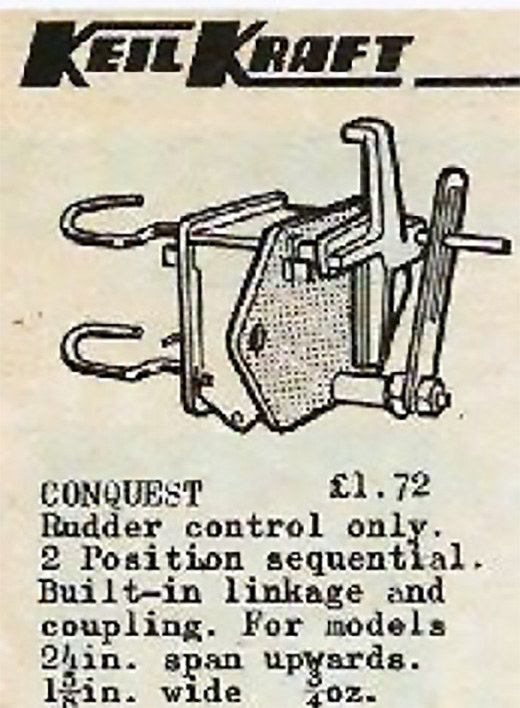

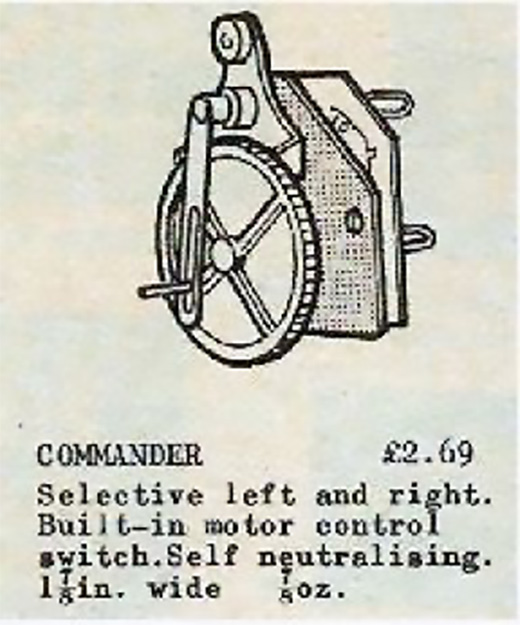

These simple systems utilized the forerunner of the servo units we know and recognize today, they used either a rubber motor powered, or a clockwork powered "Escapement" unit. The rubber-powered one was the most popular as it was lighter and very reliable. There were mainly 2 types, these were either a "Sequential" or "Compound". The first ones were sequential, when the rubber motor was wound up and the RC unit switched on the rudder would be at neutral. With the first press of the button, the rudder would go full right (no proportional control in these days) and would stay full right until you let go of the button when it would then go back to neutral. With the next press of the button, the rudder would go left, then back to neutral once the button was released, then the sequence would start all over again. So, you had to always remember which way you last turned, if you wanted to go right, then right again, you had to press the button twice to quickly skip the left rudder. The "Compound" escapement was a revelation when this came out, it took out the remembering which way you last turned. As per the sequential unit, without the button pressed the rudder would be neutral, but then, one press would give you right, and two presses of the button turned you left, this system was very popular for quite a few years.

For those that could afford them, there were the multi-channel reed systems, these enabled you to have multiple escapements installed in the model to give you rudder, elevator, and throttle controls. Once again though there was no proportional control, it was all or nothing. The later sets had sprung loaded switches replacing the buttons for the rudder and elevator, so you pushed the rudder switch either left or right, and the elevator switch up or down. The throttle switch was not sprung loaded, you either had full throttle or idle. The top pilots got very good at quickly pulsing the switches to get large smooth loops and very smooth turns.

A typical Sequential Escapement.

A typical Compound Escapement.

As the electronics revolution took off (no pun intended) the use of the single channel radios became redundant, and instead, radio systems provided proportionally coded signals which a servo mechanism could interpret using "Pulse Width Modulation" (PWM), the servo as we know it was born. The servos we buy today are based on a system that was devised by Doug Spreng and Don Mathes in the 1960s.

They developed a servo mechanism that would respond to a changing pulse width, that pulse was 1-2mS in width and repeated over a frame rate of 50Hz. The position of the output is measured by the potentiometer, it is continually compared to the commanded position of the transmitter. The servo converts these electrical commands from the receiver or flight control system back into physical movement. The movement is now proportional, meaning that the servo will now move as a proportion of how much the transmitter stick on your radio is moved.

Early servo units were quite large and heavy and were often linear, not rotary, see picture below, they also had 5 wires instead of the 3 we use today. They had the same signal wire as we still use, but they had a positive and negative wire to go in one direction, then a negative and positive wire to reverse the direction so that the servo went the other way. Also, compared to today's servos, despite their size they were not that powerful, generally they had a torque of 2-3kg if you were lucky. They also used more power, so the onboard batteries (usually Deac batteries which were an early form of NiCads) were also heavier than the batteries we use today.

Typical early linear servos with receiver.

In the mid-seventies we started to see servos with the now conventional 3-wire system, the signal wire and the positive and negative wires, the direction of the servo now being switched in the amplifier circuit. By this time most servos were now rotary as opposed to linear, but we still had a problem with all servos moving in the same direction, there was no servo reversing in the transmitters in those days. So sometimes, especially on aileron circuits, there was a bit of head scratching when sorting out the mechanical linkages to ensure the control surfaces moved in the correct sense to your transmitter control inputs. When you bought an outfit in the seventies they usually came as complete sets, transmitter, receiver, 4 servos, batteries, and charger. From memory, Futaba was the first to sort this servo direction problem, they started selling complete radio sets with 2 standard servos, and 2 that were reversed, they had different color labels to denote the difference. This was a revelation, it made installing your servos so much easier, especially if you wanted a separate servo on each aileron.

Early Futaba servos showing the different color labels for standard and reversed servos.

Since those early years, servos have continued to develop at a pace, they have gradually got smaller, lighter, and more powerful, and they were also all analog. Back in the 80s and 90s, if you wanted a powerful servo of 10kg torque or above you purchased what was then commonly known as a "Brick" servo. These were quite large and heavy but perfect for the large gas-powered models that were becoming very popular at this time. Nowadays, with the advent of digital amplifiers which give much higher holding power (this is the torque when the servo is stationary), and brushless motor servos with incredible speeds, we can have servos that are fast, and have twice the power at half the size. Other changes are the servo gears themselves, the early servos all had plastic/nylon type gears, our standard servos of today still use these materials. But, once again there has been a lot of development in this area, with the use of steel, titanium, carbon reinforced plastics, and many other tough materials to increase the strength, and durability of the gear train.

Since electric models have become very popular and are now seen as the norm, lightweight small and micro servos are in abundance, and they also have incredible amounts of torque and speed. Early servos were very slow compared to the blistering speeds we have come to expect from our servos today. This has meant the style of flying has changed over the years. 3D flying would have been impossible years ago as the response would not have been quick enough, now, as fast as you can move the sticks, the servo responds. Also, if you are a helicopter pilot, modern gyro systems require servos of high speeds, a slow servo cannot keep up with the high input speeds from the gyro as you will get a violent tail wag. A servo with the highest speed possible is what you need to get the full benefit of the gyro system.

So next time you buy some servos and set up your new model with your computer radio, please think of how we had to do things many years ago with our then basic transmitters and very basic servos. The choice we had back then was a standard servo, or a standard servo (so no choice), now there are servos for every application imaginable. Large planes, small planes, boats, helicopters, cars, buggies, robotics and so much more, all are well catered for with the vast array of RC servos that are available on the market today. Servos of yesteryear were also very much more expensive, they averaged between $20-$30 each at the time, which is roughly between $150-$250 in today's money. So, we did not have the luxury of being able to leave servos in older models when we built a new project, everything was stripped out of the old model to put into the new.

It has been amazing to watch the development of the humble servo, and RC equipment in general over the last 50 years, and what we take for granted these days

Some typical servos that are available on the market today.

HXT900 Micro Servo 1.6kg / 0.12sec / 9.8g

Corona CS238MG Metal Gear Servo 4.6kg / 0.14sec / 22g

TrackStar™ TS-900 Digital 1/8 Buggy/SCT Steering Servo 25T 18.6kg / 0.09sec / 66g

Corona DS-239MG Digital Slim Wing Servo (Metal Gear) 4.6kg / 0.15sec / 22g

---

Hear it First: Join our Mailing List

Sign up to receive new product updates, exclusive discounts, news, and more!