HobbyKing™ Mi Digital High Torque Servo 25T MG 6kg / 0.11sec / 26g

HobbyKing™ Mi Digital High Torque Servo 25T MG 6kg / 0.11sec / 26g

Awesome!

Copy and Share the Below URL

The HK Mi Series servos represent the next break through in high precision servo technology. Using Magnetic Induction, rather than a potentiometer, for an unsurpassed level of accuracy and performance.

Specs:

Voltage: 4.8v / 6v

Speed: 0.13sec/60deg (4.8v) - 0.11sec/60deg (6v)

Torque: 5kg.cm (4.8v) - 6kg.cm (6v)

Size: 35.6mm x 15mm x 31.5mm

Weight: 26.12g

Motor: Low Draw Coreless

Gear Train: Full Titanium Alloy

Spline Count: 25

Mi : Magnetic Induction, uses a magnetic rotary encoder in place of a traditional potentiometer (invented in 1877). Magnetic Rotary encoders have a longer life and suffer less wear.

-

Servo Torque(kg)(min. 0.01kg) 6.00

-

Servo Speed (Sec/60deg) 0.11

-

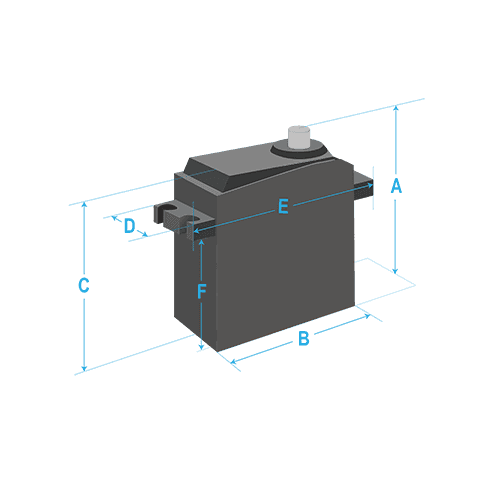

Servo A(mm) 32.00

-

Servo B(mm) 36.00

-

Servo C(mm) 30.00

-

Servo D(mm) 15.00

-

Servo E(mm) 50.00

-

Servo F(mm) 20.00

| Verified Buyer

-

Overall

-

Quality

-

Value

Certified Buyer Rated

Jan 15, 2016

Wolf | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

Aug 03, 2015

| Verified Buyer

-

Overall

-

Quality

-

Value

Certified Buyer Rated

Nov 22, 2013

| Verified Buyer

-

Overall

-

Quality

-

Value

Certified Buyer Rated

Jul 12, 2013

Egg Man | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

Nov 17, 2012

Egg Man | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

Oct 25, 2012

Motote | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

Feb 25, 2012

Wadsta | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

Feb 02, 2012

| Verified Buyer

-

Overall

-

Quality

-

Value

Certified Buyer Rated

Feb 02, 2012

| Verified Buyer

-

Overall

-

Quality

-

Value

Certified Buyer Rated

Jan 10, 2012