Turnigy 80-100-A 180Kv sin escobillas Outrunner (eq: 70-55)

Turnigy 80-100-A 180Kv sin escobillas Outrunner (eq: 70-55)

Awesome!

Es un monstruo!

El motor más grande que hemos tenido!

Apretados, bobinas de cobre de espesor y 48SH imanes hacen que este motor una potencia real. El motor también tiene v2 atornilladas tapas laterales debido a la amoung de par motor produce este motor!

Activa: 6

Potencia máxima: 7000W

Resistencia: 17ohm

Inactivo actual: 3.5A

ESC: 150A

Voltaje de entrada: máx. 48V

Kv: 180 rpm / V

Peso: 1812g

Eje: 12mm

Rango de voltaje: 20-48v

No corriente de carga: 3.3A

Equivalente: motor de gas 60-80cc

-

Kv (rpm / v) 180.00

-

Corrientes max (A) 0.00

-

Resistencia ( MH ) 17.00

-

Max Voltaje ( V ) 48.00

-

Potencia ( W ) 7000.00

-

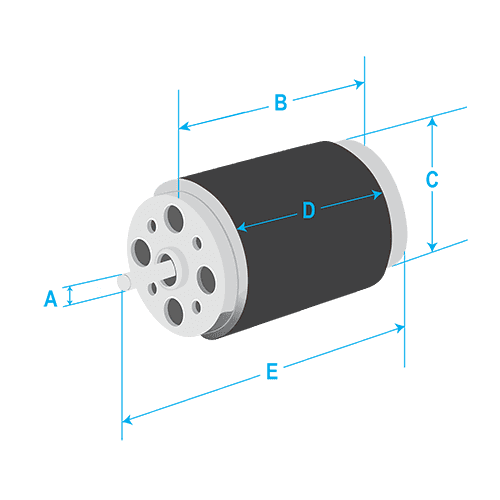

Un eje ( mm ) 12.00

-

B Longitud ( mm ) 106.00

-

C Diámetro ( mm ) 80.00

-

Puede longitud D ( mm ) 76.00

-

Longitud Total E ( mm ) 220.00

Regístrese para subir videos, por favor Iniciar Sesión o registrarse

Regístrese para escribir reseñas, por favor Iniciar Sesión o registrarse

lukas | Comprador verificado

-

Overall

-

Quality

-

Value

Customer Rated

May 09, 2012

ken | Comprador verificado

-

Overall

-

Quality

-

Value

Customer Rated

Apr 17, 2012

domsizz | Comprador verificado

-

Overall

-

Quality

-

Value

Customer Rated

Jan 28, 2012

Arvid | Comprador verificado

-

Overall

-

Quality

-

Value

Customer Rated

Jun 18, 2011

jjpextra | Comprador verificado

-

Overall

-

Quality

-

Value

Customer Rated

Jun 11, 2011

dennis | Comprador verificado

-

Overall

-

Quality

-

Value

Customer Rated

Apr 15, 2011

LURCH | Comprador verificado

-

Overall

-

Quality

-

Value

Customer Rated

Mar 25, 2011

juicedparamotors.yolasite.com | Comprador verificado

-

Overall

-

Quality

-

Value

Customer Rated

Nov 29, 2010

Cliente | Comprador verificado

-

Overall

-

Quality

-

Value

Customer Rated

Nov 25, 2010

mickreeves | Comprador verificado

-

Overall

-

Quality

-

Value

Customer Rated

Nov 06, 2010

| DATA SHEET - DIMENSIONS | Download [683] |

Regístrese para subir archivos.

Por favor registrarse o registrarse para empezar a ayudar a los aficionados ahora!