Turnigy EasyMatch Serie G46 - Eje de reemplazo

Turnigy EasyMatch Serie G46 - Eje de reemplazo

Turnigy EasyMatch Serie G46 - Eje de reemplazo

Especulación.

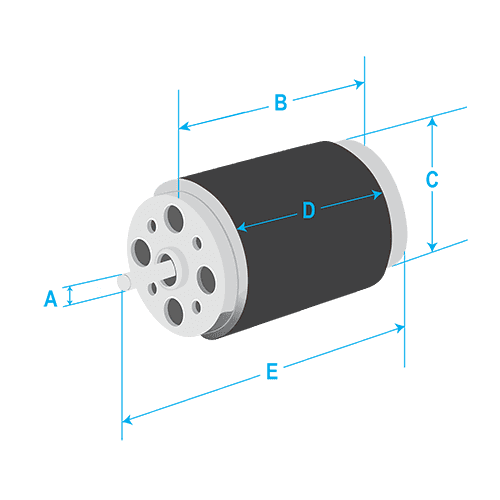

Longitud del eje: 76mm

Diámetro del eje: 6 mm

Regístrese para subir videos, por favor Iniciar Sesión o registrarse

Regístrese para escribir reseñas, por favor Iniciar Sesión o registrarse

Kiwibob | Comprador verificado

-

Overall

-

Quality

-

Value

Replacement shaft

Jan 28, 2022

David B | Comprador verificado

-

Overall

-

Quality

-

Value

G46 back to life

Nov 20, 2021

Eric | Comprador verificado

-

Overall

-

Quality

-

Value

Very slow delivery!

Dec 06, 2020

Rusty | Comprador verificado

-

Overall

-

Quality

-

Value

Shaft

Nov 19, 2019

Gary | Comprador verificado

-

Overall

-

Quality

-

Value

Nice

Oct 03, 2019

Regístrese para subir archivos.

Por favor registrarse o registrarse para empezar a ayudar a los aficionados ahora!