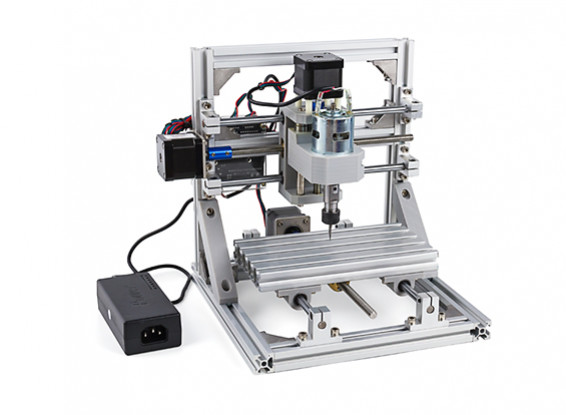

T8 DIY 3-Axis CNC Milling Machine w/Arduino and Grbl

T8 DIY 3-Axis CNC Milling Machine w/Arduino and Grbl

Whether it's for getting your artwork onto jewelry, producing a custom PCB, or creating stunning 3-dimensional designs on plastic, wood, acrylic or similar materials, the T8 DIY 3-Axis CNC Milling Machine will be the perfect addition to your workshop. The T8 now comes with a universal chuck allowing for different diameter cutting tools to be fitted.

The T8 is a high-resolution milling machine capable of producing 3D effects on surfaces as well as standard 2-dimensional engraving on flat surfaces. Its clever design leaves everything accessible while still being compact enough to move around easily.

A tried and tested 775 brushed motor drives the engraving bit with stepper motors to look after the linear positioning to give you accuracy, speed (500 to 600mm/sec - 4 times faster than industry standard) and reliability. The Arduino compatible control board is able to drive a laser head. So you can swap the spindle motor for a laser to give even more versatility.

The open source Grbl control system includes full acceleration management incorporating a look ahead function to give super-smooth acceleration and jerk-free cornering to ensure a high-quality end product.

For a no-nonsense, low-cost milling/engraving tool, the T8 DIY 3-Axis CNC Milling Machine is hard to beat!

Features:

• Now with universal chuck for different diameter cutting tools

• Versatile and practical engraver

• Up to 4 times faster than standard

• 3D capable

• Accepts standard G-code

• Open source GRBL control

• Uses Arduino Grbl w/Amtel AVR chip

• High precision stepper motors

• Durable 775 brushed engraver motor

• Ideal for desktop use

• Aluminum frame

• Stainless steel screw rods

• Software supports Windows 7/XP/8/10

• USB interface

• Laser-head compatible

• Arduino compatible control board

• CNC Grbl Board

• A4988 Motor driver expansion board

Specs:

Input voltage: 24V/5A plus 12V/5A

Stepper motors: L42BYGH34-1334A

Spindle motor: 775 Brushed

Max travel distances:

X: 160mm

Y: 100mm

Z: 45mm

Repeat positioning accuracy: 0.1~0.05mm (no load)

Max material depth: 30mm

Chipset: Atmega 328

Dimensions: 240 x 220 x 200mm

Weight: 3800g

Included:

T8 DIY 3-Axis CNC Milling Machine Kit

24V/5A Power supply

12V/5A Power supply

Assembly tools

USB Lead

Brush

Accessories

Registrati per caricare video, per favore accedi o registrati

Registrati per scrivere recensioni, per favore accedi o registrati

mill | Acquirente verificato

-

Overall

-

Quality

-

Value

Great price nearly impossible to use

May 08, 2019

Dave | Acquirente verificato

-

Overall

-

Quality

-

Value

Falls short - just a touch

Dec 14, 2018

| cnc 1012 | Download [39] |

Registrati per caricare i file.

Per favore accedi o registrati per iniziare subito ad aiutare gli hobbisti!