Turnigy Park300 Brushless Outrunner 1380kv

Turnigy Park300 Brushless Outrunner 1380kv

Un motore di qualità, costruito appositamente per gli aerei progettati per volare con un 77 watt brushless outrunner.

Spec.

Batteria: 2 ~ 3 cellulare /7.4~11.1V

RPM: 1380kv

Corrente max: 7A

Corrente a vuoto: 8V / 0.4A

Capacità di corrente: 9A / 15sec

Resistenza interna: 0,33 Ohm

Peso: 24g (ad esclusione di connettori)

Diametro del pozzo: 3mm

Dimensioni: 37x28mm

richiesto;

10A ESC

2S ~ 3S Li-Po / 6 ~ 8 celle Ni-MH / Ni-Cd

6x5 ~ prop 8x3.8

Adatto per lo sport e scala gli aerei di peso da 8 a 12 once (225g-340g).

-

Kv ( rpm / v ) 1380.00

-

Correnti Max (A) 7.00

-

Resistenza ( mh ) 0.00

-

Max Tensione (V ) 11.00

-

Potenza ( W ) 77.00

-

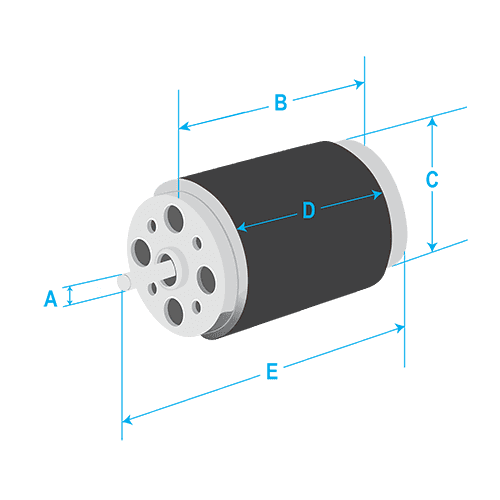

Albero A ( mm ) 3.00

-

Lunghezza B ( mm ) 25.00

-

Diametro C ( mm ) 28.00

-

Can Lunghezza D ( mm ) 9.00

-

Lunghezza totale E ( mm ) 37.00

Registrati per caricare video, per favore accedi o registrati

Registrati per scrivere recensioni, per favore accedi o registrati

Alain | Acquirente verificato

-

Overall

-

Quality

-

Value

Recommandé

Sep 12, 2017

Kurt | Acquirente verificato

-

Overall

-

Quality

-

Value

Customer Rated

Apr 06, 2017

Luis | Acquirente verificato

-

Overall

-

Quality

-

Value

Customer Rated

Apr 06, 2017

John | Acquirente verificato

-

Overall

-

Quality

-

Value

Customer Rated

Apr 06, 2017

Ange Dominique | Acquirente verificato

-

Overall

-

Quality

-

Value

Customer Rated

Apr 06, 2017

Lizarazu | Acquirente verificato

-

Overall

-

Quality

-

Value

Customer Rated

Apr 06, 2017

Alain | Acquirente verificato

-

Overall

-

Quality

-

Value

Customer Rated

Apr 06, 2017

Gaston | Acquirente verificato

-

Overall

-

Quality

-

Value

Customer Rated

Apr 06, 2017

Alain | Acquirente verificato

-

Overall

-

Quality

-

Value

Bien

Mar 21, 2017

Pierre | Acquirente verificato

-

Overall

-

Quality

-

Value

Customer Rated

Oct 31, 2015

| Shaft diameter measurement | Download [1353] |

| Turnigy Park300 1380kv & OrangeRx T-SIX | Download [5898] |

Registrati per caricare i file.

Per favore accedi o registrati per iniziare subito ad aiutare gli hobbisti!