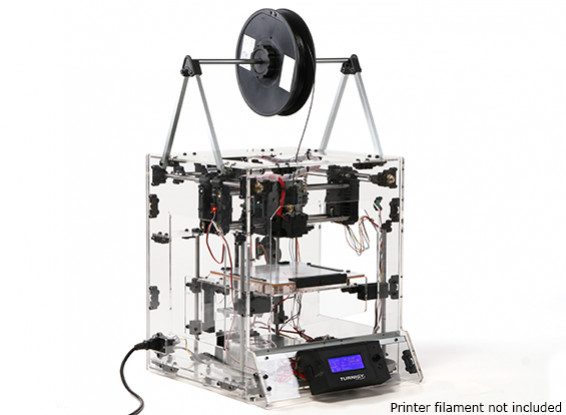

Turnigy Fabrikator 3D Printer (UK Plug)

Turnigy Fabrikator 3D Printer (UK Plug)

Awesome!

Copy and Share the Below URL

Turnigy Fabrikator, our worst kept secret is here; what we didn’t leak out was how good it is. This is the best value for money printer on the market with the features and quality of printers three times the price.

No longer is 3D printing technology the exclusive realm of hard-core technophiles and industrial designers, it is now accessible to anybody with a computer and the ability to put flat pack furniture together. Whether you are into planes, multi-rotors, cars, boats, helicopters, robotics, trains or even anime figurines the Fabrikator will soon become your most versatile tool. Can’t find that rare part for your old model or you just want to modify an existing piece? Now you can print what you want, when you want it.

Turnigy Fabrikator is able to use the ABS and PLA filaments already available from a HobbyKing warehouse near you and can print high quality finishes achievable at 150mm/sec. Gone are the days of setting the printer before you go to bed and hoping the job is finished when you get up. 3D printers used to be just for pre-production models and proof of concept for designs, but now you can design, print and use the part in all sorts of applications.

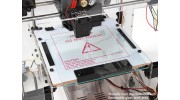

This incredibly well engineered printer featuring a rock solid frame, super stable quad rail supported print plate, high quality NEMA Class motors, removable glass print platform and twin belt Y axis drives means you are able to print highly accurate pieces time and time again, without the need for constant mechanical adjustments.

This is not just a great machine, we have taken it a step further and have created a series of videos that will guide you step-by-step to build and set up your printer along with a unique live dynamic and updatable trouble shooting guide that is available under the files tab below, but because the Fabrikator is so simple to use you won’t be needing much help.

To make the Fabrikator as affordable as possible for you we have designed it as a simple to put together flat pack kit, which if you follow the excellent manual in conjunction with the video series you will have it built in a few hours. It’s so easy we got our least technical staff member to put one together and he had it going in less than six hours.

Features:

• Ball bearing liner rods

• Rolled lead-screw with anti-backlash drive

• Phenolic heat stabilized bed W/removable Glass print area

• Heated print bed

• NEMA 23 and 17 motors

• 4 rod supported print plate for high speed printing

• 6 sided full printer support for high accuracy

• SD card cable free printing|

• PLA and ABS filament compatible

• Top feed anti-bind spool feed

• Twin print cooling fans

• 2A Heatsink stepper drivers with active cooling

• 220~110V A/C compatible

• Homing and Limit switches

• Full LCD GUI with on the fly tuning

• Large 150x150x100mm print area

• Dual bearing supported twin belt Y axis drive

• Heavy Duty 12Volt 29Amp Power supply

• Open Source control Architecture and support

• Full Parts support and future expandability platform

Specs:

Overall size: 360x400x600mm

Print size: 150x150x100mm

Nozzle diameter: 0.4mm

Filament diameter: 1.75mm

Print speed: up to 300mm/sec

Print platform: Phenolic heat stabilized bed with removable glass print platform

Filament type: ABS and PLA

Required:

Filament of your choice

-

Turnigy Fabrikator 3D Printer

Turnigy Fabrikator 3D Printer

jeremy | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

Oct 22, 2015

Hadtstec | Verified Buyer

-

Overall

-

Quality

-

Value

Certified Buyer Rated

Aug 13, 2015

harlequin2 | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

Jun 26, 2015

Harry | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

May 28, 2015

John | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

May 18, 2015

Rustydiver | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

May 12, 2015

Rod | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

Apr 27, 2015

Simon | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

Apr 26, 2015

ausi1972 | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

Apr 26, 2015

Phil | Verified Buyer

-

Overall

-

Quality

-

Value

Customer Rated

Apr 24, 2015

| No File Name | Download [446] |

| turnigy 3d with pla filament | Download [651] |

| Fabrikator Q&A | Download [228] |

| Fabrikator Q&A | Download [228] |

Only registered users can upload files.

Please log in or register to start helping your fellow hobbyists today!