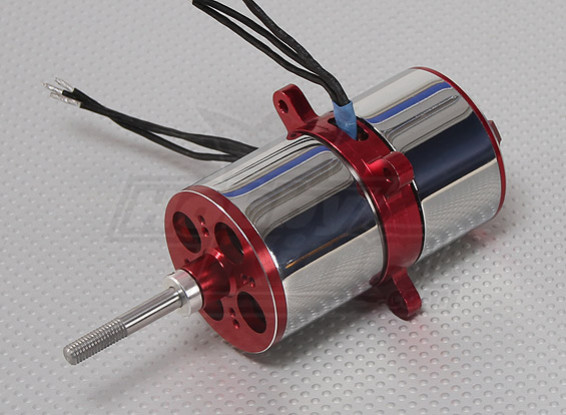

Contra Rotating CR50L Brushless Outrunner Motor inc Radial Mount Motor

Contra Rotating CR50L Brushless Outrunner Motor inc Radial Mount Motor

Awesome!

Acessórios

Esta rotação do motor brushless monstro Contra é ideal para grandes navios de padrões e modelos em escala capazes de executar múltiplas 6s pacotes.

especificações:

Dimensões: 50mm x 90 milímetros

Comprimento total: 143 milímetros (Motor)

Peso: 696g (748G com montagem)

Diâmetro do eixo (frente): 6mm

Diâmetro do eixo (traseiro): 13 milímetros

KV: 320 rpm / v

Max Tensão: 8s 29.6v (por motor)

Max Amps: 80A (Per Motor)

Prop Tamanho: 17x10 Max (8s)

Thrust: 16 kg

-

Kv ( rpm / v ) 320.00

-

Correntes Max (A) 80.00

-

Resistência (MH ) 0.00

-

Max Tensão ( V) 30.00

-

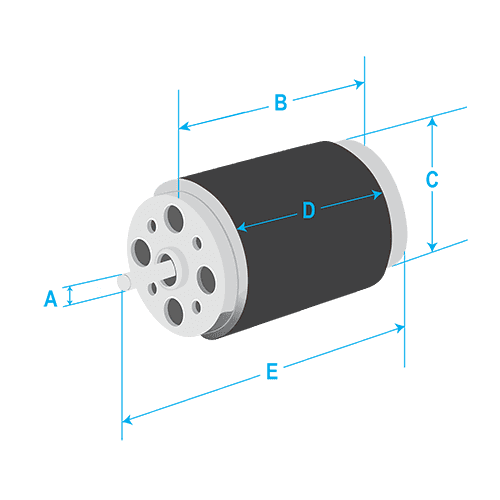

Shaft A ( mm) 6.00

-

Comprimento B (mm) 88.00

-

Diâmetro C ( mm ) 50.00

-

Pode Comprimento D (mm) 34.00

-

Comprimento Total E ( mm) 143.00

Registre-se para enviar vídeos, por favor assinar em ou registar

Registre-se para escrever comentários, por favor assinar em ou registar

scatsob | Comprador Verificado

-

Overall

-

Quality

-

Value

Customer Rated

Jan 13, 2012

scatsob | Comprador Verificado

-

Overall

-

Quality

-

Value

Customer Rated

Nov 15, 2011

| CR50-1 | Download [323] |

| CR50-2 | Download [238] |

| CR50-3 | Download [440] |

Registre-se para fazer upload de arquivos.

Por favor assinar em ou registar para começar a ajudar amadores agora!